2022-11-17

What are the advantages of the indirect method for zinc oxide production?

The wide application of indirect zinc oxide is due to its various advantageous properties, making it a popular product in the market. However, there are many points of knowledge that need to be understood when using it, after all, many users are not aware of these. Next, the editor will introduce the advantages of indirect zinc oxide. Those who are interested can read it.

2022-11-04

Specific details of zinc oxide in phosphating liquid

Zinc oxide in normal temperature rust preventive phosphating liquid is widely used in the phosphating rust prevention treatment of ferrous metal materials and parts, providing a coating promoter for electroplating and spraying technology. Its main feature is that it can be phosphated at room temperature. During processing, workpieces can be stored for 2-3 days without rusting. It is non-toxic and has no irritating odor, resulting in a uniform coating with strong adhesion and good corrosion resistance.

2022-07-28

AI website building technology is emerging: a new revolution in website development

AI-powered website building technology is emerging in the e-commerce field, providing online businesses with a new choice for website creation. This technology not only simplifies the website building process but also helps e-commerce businesses improve user experience and sales conversion rates through personalized recommendations and intelligent marketing functions. This article will focus on how AI website building technology plays a role in e-commerce and its impact on the future of the industry.

2022-07-19

Formulation and component analysis of zinc oxide in phosphating solution

Zinc phosphate is a mixed chemical reagent mainly composed of zinc nitrate, zinc oxide, nitric acid, and water. It is mainly used for rust removal at room temperature. Zinc phosphate is a pretreatment process before steel coating. It can improve the rust prevention ability of steel and increase the bonding force between the material and the paint. After the zinc phosphate itself reacts with the substrate, a dense chemical conversion film will be formed on the surface of the substrate...

2022-06-17

Composition of zinc oxide in phosphating solution

Low-temperature zinc-based phosphating liquid zinc oxide is suitable for various primers, liquid and powder products before coating. It can be phosphated by immersion or spraying, and is suitable for automotive and appliance coatings. It features fast phosphating speed, less sludge, and wide applicability: ultra-low temperature rapid phosphating, no heating required, immersion and spraying, simple management, suitable for various workpieces and processes; long cycle, less frequent addition, simple and convenient to use.

2022-05-18

Zinc oxide in phosphating liquid is mainly used in the manufacturing of various batteries and plates, as well as flame retardant additives and rubber vulcanization accelerators. Due to its good insulation and heat resistance (it does not melt at high temperatures), it is widely used in many fields. So, what are the factors affecting the price of zinc oxide in phosphating liquid? Generally speaking, raw material costs account for about 60% of the total cost, labor costs account for 20-30%, and product quality determines market conditions...

2022-05-18

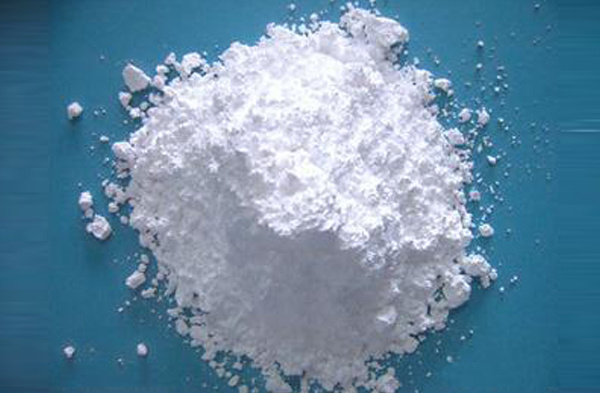

Zinc oxide manufacturer of phosphating liquid: Active zinc oxide is an excellent vulcanization activator. Rubber zinc oxide is a white or yellow fine powder, which is a nano-composite product made by introducing advanced foreign production and processing technology according to the requirements of the rubber industry for zinc oxide. Its high activity and superior performance have been widely used by users. Test results show that it is widely used in tapes, rubber conveyor belts, V-belts, motorcycle tires...

2022-05-18

What is rubber-grade zinc oxide?

Rubber-grade zinc oxide is a white hexagonal crystalline powder, odorless, non-toxic, fine in texture, with special small size effect and surface activation effect. It is an active additive. Compared with indirect zinc oxide and direct zinc oxide, this product has a larger specific surface area, therefore, it has higher activity and good dispersibility in application. Rubber and plastic-specific active zinc oxide has low content of heavy metal impurities...

2022-03-03

How should the price of zinc oxide be calculated?

When purchasing zinc oxide products, the price of zinc oxide will fluctuate depending on the zinc content. The higher the zinc content, the higher the price of zinc oxide. For example, the price of zinc oxide also varies depending on the brand. Well-known brands with high influence will naturally have higher prices, while lesser-known brands will have lower prices. Due to differences in production processes and technology, the prices of imported and domestic zinc oxide will also differ.

2022-02-15

Zinc oxide manufacturers of phosphating liquid: Uses of zinc oxide

Zinc oxide manufacturers of phosphating liquid: Requirements and characteristics of zinc oxide for phosphating liquid. Zinc oxide manufacturers of phosphating liquid believe that the requirements for zinc oxide in phosphating liquid are relatively high. First of all, the content of zinc oxide. From the reaction formula, if the zinc oxide content in the zinc phosphate reaction does not reach the standard or the purity is insufficient, two situations will occur. More raw materials that can react with phosphoric acid will be used, and the generated substances will also affect the purity of the product.